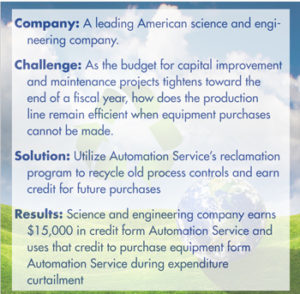

As capital improvement and maintenance budgets tighten significantly during the last months of the budget year, production was slowed due to lack of repairs and improvements at a leading American science and engineering company. No funds were available for replacement of aging or ineffective equipment, other than necessary improvements or repairs to comply with safety or environmental regulations.

Additionally, at this time, the company was gaining a stockpile of old equipment that was taking up valuable space in the maintenance warehouse. Simply disposing this stockpile would incur disposal fees.

Jerry Butz was working for the science and engineering company at the time as an instrument reliability engineer and was responsible for improving performance and reliability of instrumentation and control loops. However, Butz was repeatedly directed to defer costs to the next fiscal year due to budget restrictions. He needed to find a solution…

Automation Service Offers an Alternative to Disposal

After being introduced to Automation Service by a colleague, Butz learned of the company’s free-of-charge reclamation program for old process control equipment. Automation Service would come to Butz’ plant, pull all of the eligible stockpile equipment, and offer credit to purchase necessary instrumentation from Automation Service. Not only had Butz found a way to efficiently clear out the equipment that had been collecting dust, but he also earned credit for future purchases. He used the $15,000 in credit to purchase much needed equipment and improved his company’s production outputs.

“Our reclamation program really is win-win for all parties involved,” said Angie Kamp, senior account executive at Automation Service. Jerry Butz was able to clean up some clutter, keep it out of a landfill, and earn valuable credit that he turned into much needed equipment.

Old Parts Turn Into New Improvements

At the company’s morning meetings, Butz was able to tell his production team and fellow engineers of the improvements he was making in the process control loops, control valves and other parts that fell under his responsibility.

Eventually, his manager began to wonder how Butz was able to accomplish all these improvements during a time when all non-critical spending was restricted.

“With all the equipment we recycled from the stockpile, we earned $15,000 in credit to purchase instrumentation from Automation Service,” said Butz. “My boss was puzzled at first, but later impressed that I was able to continue making improvements without spending any money from the budget.”

Through Automation Service’s process controls recycling program, Butz was able to treat the stockpile equipment as the asset it was. Improvements in plant reliability were made and projects were moved forward that otherwise wouldn’t have. Butz was so impressed with Automation Service and how it did business that he now works for them as Director of Customer Engineering.

About Automation Service

Founded in 1956, Automation Service is a global leader in high-quality remanufactured process controls. The company is known industry-wide for outstanding quality, on-time deliveries and exceptional service and support. Headquartered in St. Louis, Missouri, Automation Service is proud to say that its products are “Re-Made in the USA.” For more information, please visit www.automationservice.com or www.automationservice.com/recycling.