Whether you’re refining your process controls in an oil field, chemical manufacturing plant, pulp and paper shop, or an energy production facility, determining which manifold you need for your transmitters can be a little tricky. To help you in the selection process, we put together this quick visual guide help to get you started.

Whether you’re refining your process controls in an oil field, chemical manufacturing plant, pulp and paper shop, or an energy production facility, determining which manifold you need for your transmitters can be a little tricky. To help you in the selection process, we put together this quick visual guide help to get you started.

First, let’s break down manifold assembly types and their common applications.

Automation Service Manifold Assembly Types & Sizes

Manifolds are used to isolate process connection(s) using 2, 3, or 5 valves.

2-valve manifolds are used for gauge pressure transmitters.

- Application: When you need to isolate the transmitter and vent the pressure off

3-valve manifolds are used on differential pressure transmitters.

- Application: When you need to block each process connection or equalize two sensor diaphragms

5-valve manifolds are used on differential pressure transmitters.

- Application: When you need to block, equalize, and vent two process connections

Now, let’s move on to different types of manifolds.

Manifold types

There are four types of manifolds — direct connect, coplanar, traditional, and conventional.

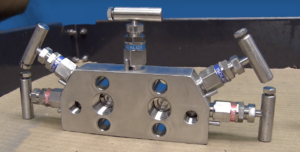

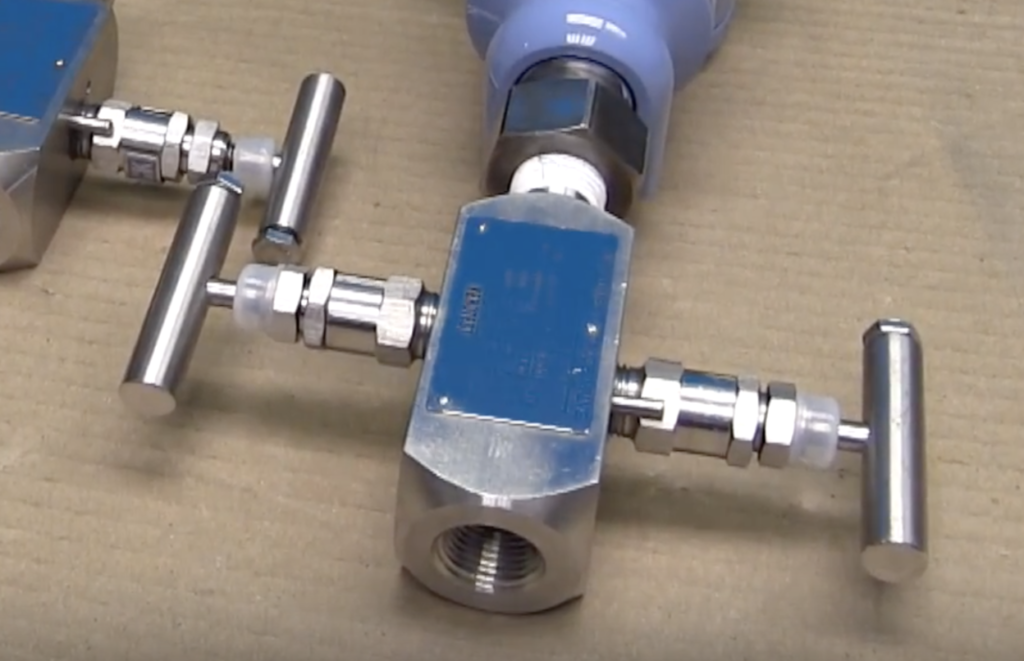

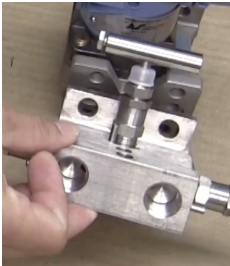

Direct connect/inline manifolds

Direct connect manifolds, also called inline, or block and bleed manifolds, have either female or male process connections. This style manifold connects to transmitters using male National Pipe Thread (NPT).

These manifolds are only available as a 2-valve assembly with a ½” NPT process connection. Female process connections are standard for these manifolds, but male process connections are also available.

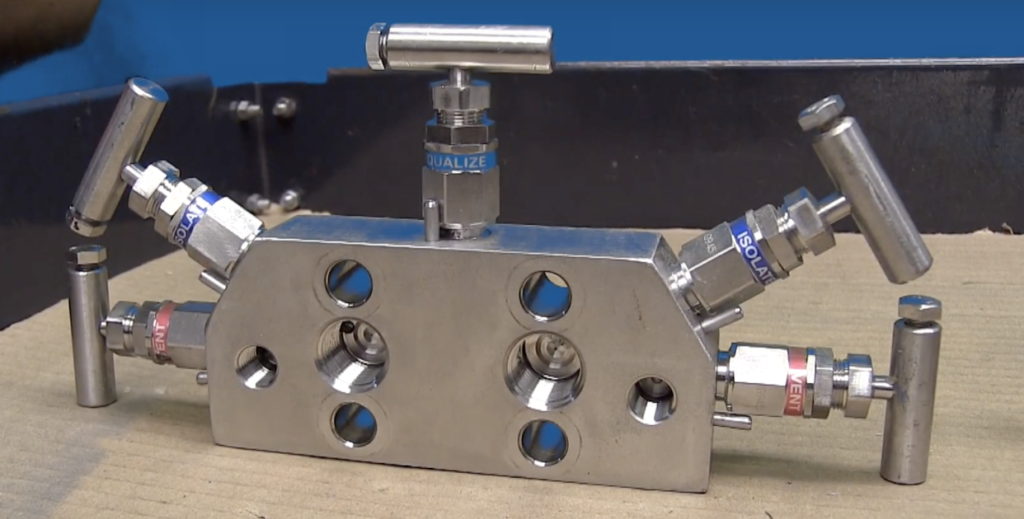

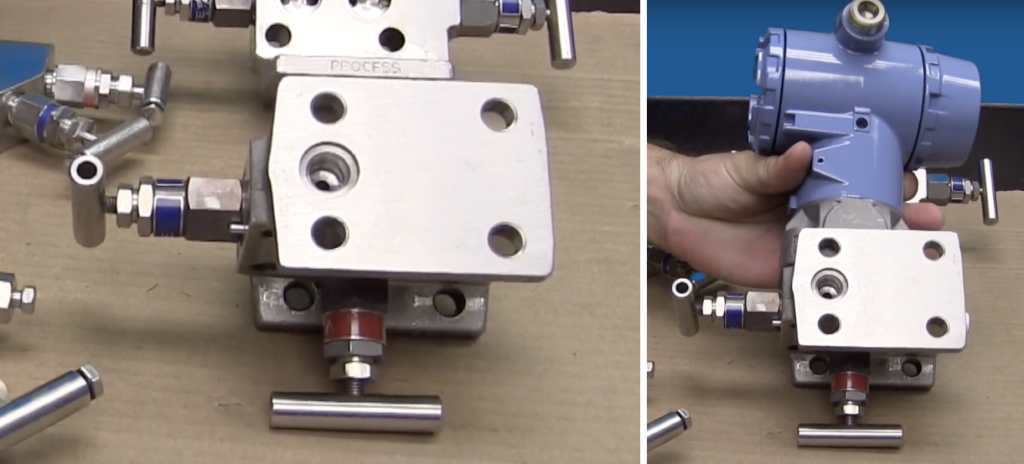

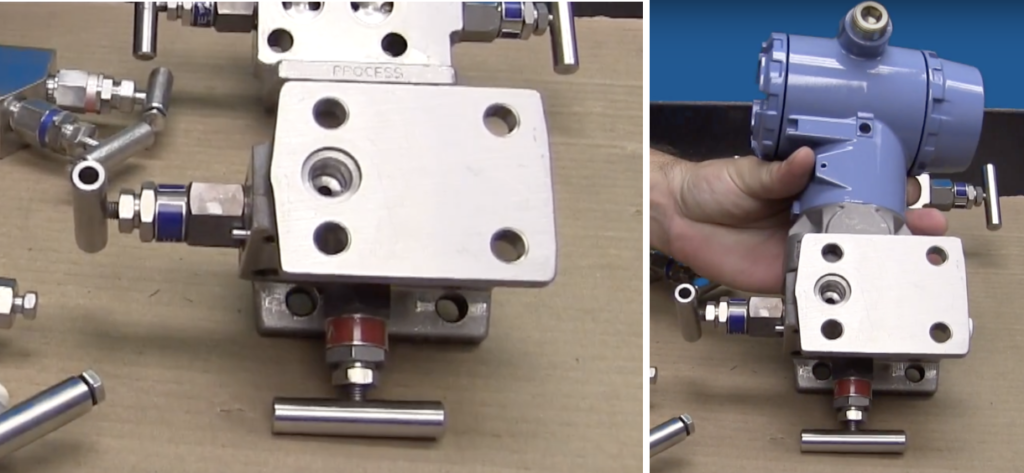

Coplanar manifolds

Coplanar manifolds have the process connection coming in from the bottom and don’t require a process flange. They’re available in 2, 3, or 5-valve assemblies, with a 5-valve gas metering pattern also available. You can get coplanar manifolds with ½” or ¼” process connection sizes.

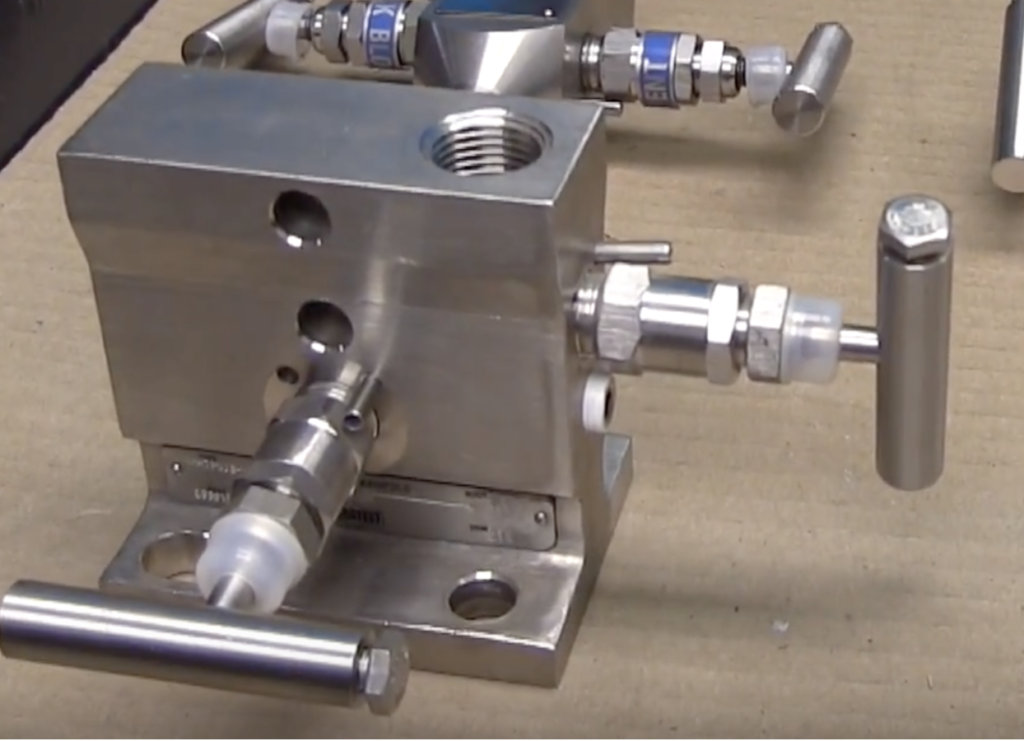

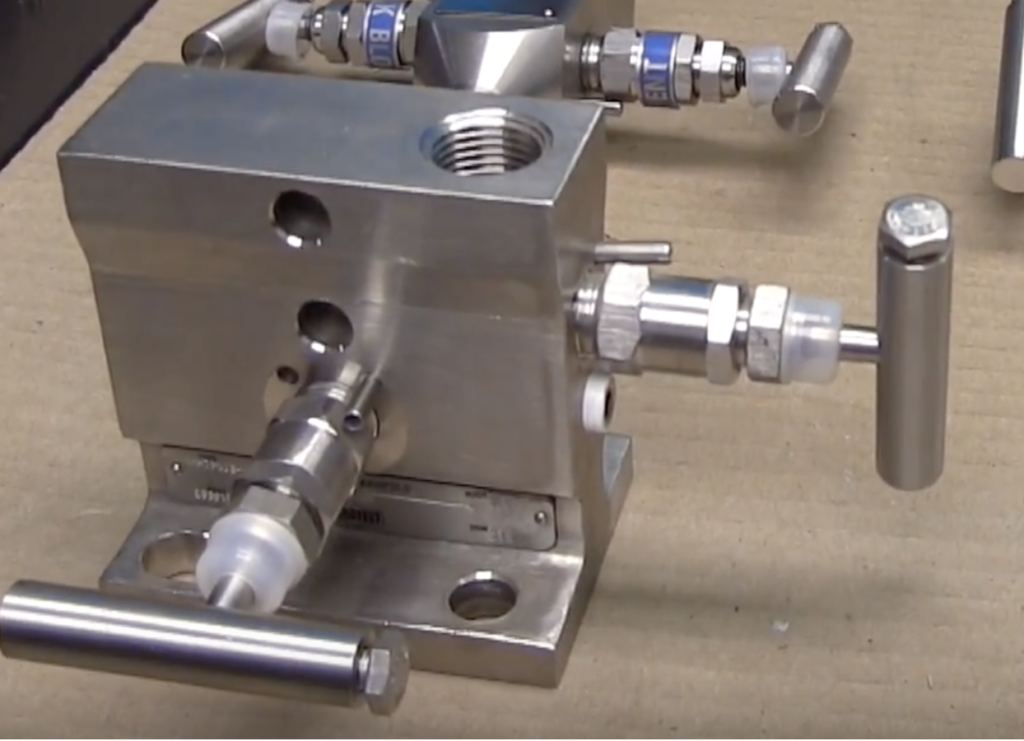

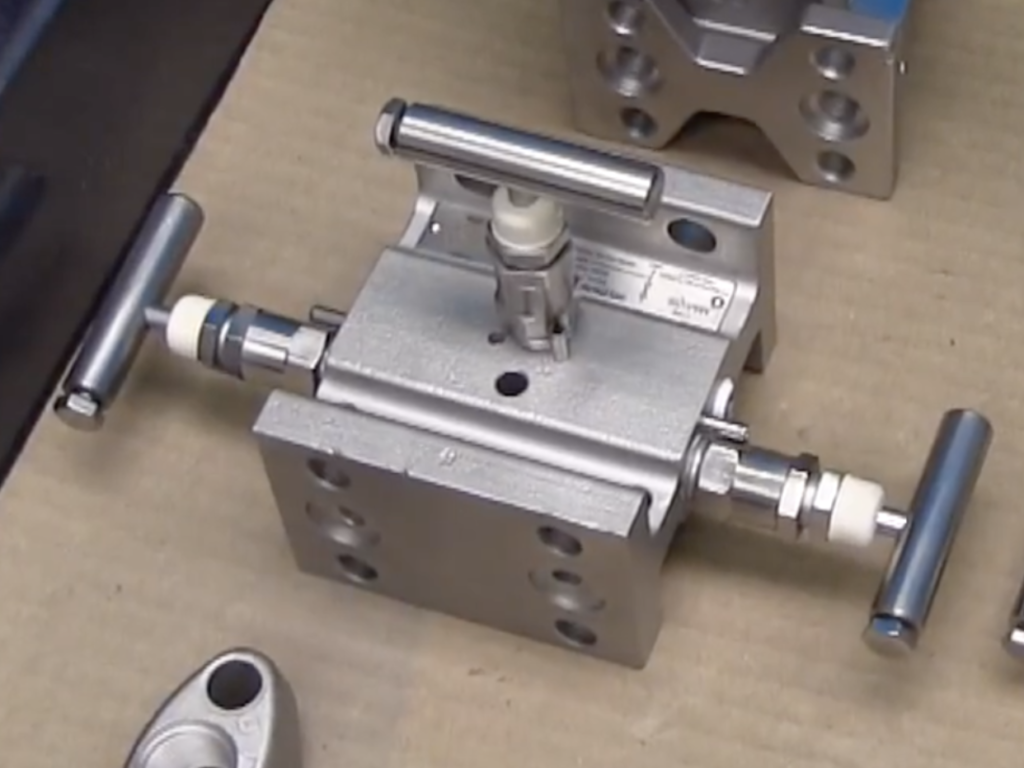

Traditional manifolds

Traditional manifolds have a connection on the side. You can get them in 2 or 3-valve assemblies. Some traditional manifolds require you use a flange and those that don’t. These manifolds are available in ½” and ¼” process connections.

Conventional Manifolds

If you need to mount your manifold on the side of a process flange instead of directly on a pressure transmitter sensor, you must use a conventional manifold. You might find these flanges referred to as alternative or traditional flanges. Conventional manifolds are available as 2, 3, or 5-valve. The instrument side has a 2 ⅛” center-to-center connection.

Sizes and styles of process connections

Flange to flange is used with process connectors, also called footballs or process adapters. They’re available in ¼” and ½”.

Flange to thread is a standard ½” NPT connection.

For more information, download our manifold selection guide.