If you’ve never thought about corrosion on the inside of your actuator, you’re in good company. The internal components of actuators — diaphragm plates, actuator travel stops, actuator stems, springs, etc. — aren’t easily accessible for visual inspection, which makes their condition difficult to monitor. As a result, corrosion often goes undetected until it’s in the advanced stages.

If you’ve never thought about corrosion on the inside of your actuator, you’re in good company. The internal components of actuators — diaphragm plates, actuator travel stops, actuator stems, springs, etc. — aren’t easily accessible for visual inspection, which makes their condition difficult to monitor. As a result, corrosion often goes undetected until it’s in the advanced stages.

Here’s how the internal components of actuators can become damaged:

The diaphragm casings are exposed to the instrument air used to power the actuator. In most applications, this air is less than “instrument quality,” meaning clean and dry. Dry is the operative word here — any moisture in the air, whether it’s created during the compression of humid air or not filtered out, can get into the diaphragm casings and start to corrode the internal components.

Even the side of the diaphragm casing that is not exposed to instrument air is still exposed to the surrounding environment. As the actuator “breathes,” each inhalation draws in air from the immediate surroundings, and that air may also contain moisture. The spring barrels are similar — while they don’t typically come into contact with instrument air, they are exposed to the surrounding environment.

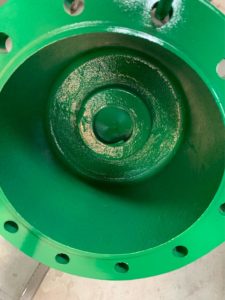

The bottom line is that if your actuator isn’t protected as well on the inside as it is on the outside, then the job is only half done. Not all repairs, rebuilds, and remanufactures are the same.

At Automation Service, we take the precaution of painting the inside surfaces of the actuator diaphragm casings and spring barrels to protect against corrosion. This extends the life of the equipment and saves you from costly repairs. If you have any questions, please get in contact.